Complete underground pipe inspection data directs efficient planning and operations

National Underground Group’s multi-sensor inspection technologies provide certified National Association of Sewer Service Companies (NASSCO) inspection data that enables municipalities, utility providers, pipe inspection contractors and engineering firms to produce effective and efficient preventive maintenance programs. Determining pipe conditions is also essential for prioritizing project requirements and sound budgetary planning.

Comprehensive portfolio of multi-sensor pipe inspection technologies for any application

Without a thorough and accurate assessment that provides quality data, successfully undertaking a major pipe infrastructure project can be difficult and possibly hazardous.

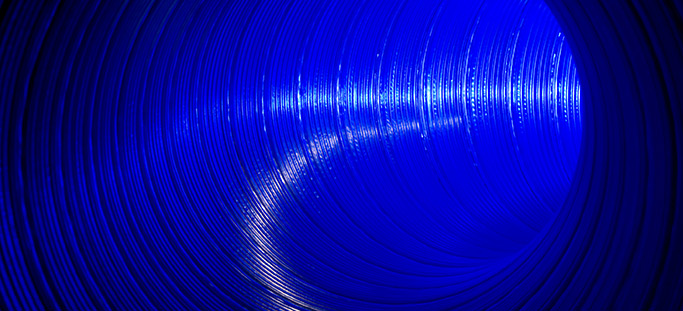

Laser Profiling performs inspections using a projected laser light to measure aspects of pipes in diameters from 6 to 120 inches while providing automatic analysis of pipe condition and ovality, laterals, water levels and capacity. This enables contractors, engineers or a municipality to determine internal pipeline conditions before, during and after rehabilitation.

The laser profiling system uses a laser tool in tandem with a pipeline TV camera. As the camera is directed through the line, the laser tool projects a ring of laser light onto the internal surface of the pipe, creating a digital profile of the sewer line. The resulting inspection can be viewed live or recorded to video (tape, CD or DVD) and the profile data can be provided in standard formats, including JPEG, BMP and TIFF.

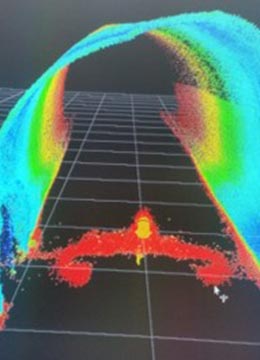

LiDAR Profiling uses light detection and ranging (LiDAR) to provide accurate inspection data for proactive repair and replacement of pipes in diameters of 6 to 60 inches. To those considering infrastructure rehabilitation, the system offers a number of benefits:

- Collects data necessary to comply with local, state and federal agencies, and establishes baselines for state and federal grant applications

- Employs detailed assessments to identify problems and provide predictive failure analysis

- Charts accurate records to help direct expenditures

The system can be deployed inside pipes using wheel or track-mounted tools in two primary modules:

- 2D LiDAR (Solid FX) provides cross-sections of pipe up to 5400 feet in length, enabling stakeholders to determine wall loss in addition to the pipeline’s ovality and capacity.

- 3D Spinning LiDAR (FX3D) performs 360-degree scans and 3-D models of pipe up to 2000 feet in length from a robotic tractor. In addition to bend-geometry modeling (AutoCAD®), the data can be used for virtual mandrels, alignment geo-positioning, diameter/ovality and wall loss due to corrosion.

Both modules are equipped with a high-definition, closed-circuit television (CCTV) camera that quickly produces detailed pipeline condition assessments and is capable of integrating sonar in a multi-sensor system configuration.

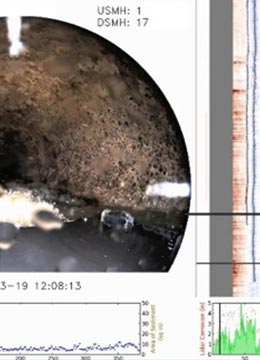

Sonar Profiling emits sound pulses and reflection measurements to provide inspection data on pipe deformation, silt and grease accumulation, and offsets and blockages in partially and fully submerged pipes. This makes it a valuable alternative to CCTV inspections, which are relegated to performing visual inspections of sewer systems above the waterline, and offers some unique advantages:

- Collects accurate and reliable inspection data from submerged and semi-submerged pipelines while they are in service, including high flow pipes and those that are surcharged, or outfalls and siphons

- Provides detailed two-dimensional profiles of the sewer pipe interior wall

- Produces composite images of pipe above and below the waterline in conjunction with CCTV

- Furnishes “real-time” cross-sectional views of pipe utilizing high-resolution/short-range sonar

The sonar profile unit can be skid, float or robotic tractor-mounted to provide mobility within pipe ranging from 18 inches to 18 feet in diameter. The unit records travel distance and internal sensors monitor its orientation, enabling users to accurately identify the location of pipe defects and deformities.

The data provided by National Underground Group’s multi-sensor inspection provides risk analysis parameters that include comparing a pipe’s condition and its likelihood of failure with the consequences of that pipe’s failure. This information can be used to establish the overall risk inspected pipe segments present.

Service Lines

Pro-Pipe

Pro-Pipe provides cross bore inspection and pre- and post-construction inspections for trenchless installations. Utilizing advanced technology and sophisticated equipment, Pro-Pipe digitally maps (GIS) underground infrastructure, provides condition scoring for prioritization and assessment, and offers comprehensive maintenance and rehabilitation.

Go to Pro-Pipe Go to Pro-Pipe Go to Pro-Pipe

Pro-Pipe

Pro-Pipe provides cross bore inspection and pre- and post-construction inspections for trenchless installations. Utilizing advanced technology and sophisticated equipment, Pro-Pipe digitally maps (GIS) underground infrastructure, provides condition scoring for prioritization and assessment, and offers comprehensive maintenance and rehabilitation.

Go to Pro-Pipe Go to Pro-Pipe Go to Pro-Pipe